Process Validation in GMP is significant to making sure the protection, efficacy, and good quality of pharmaceutical products. It will involve a series of activities created to show that the manufacturing processes constantly create products which meet predefined top quality criteria.

The process qualification phase is vital in developing self confidence from the process's capacity to continuously generate large-high-quality solutions. It provides proof which the process is underneath control and effective at Conference the desired outcomes.

The process qualification stage is significant in creating confidence inside the process's capability to persistently make large-excellent solutions. It offers proof the process is underneath Regulate and capable of Conference the desired outcomes.

The info collected in the course of this stage offers valuable insights into your process's effectiveness eventually. It allows for the identification of any tendencies or deviations within the validated point out, enabling timely corrective steps being taken.

The verification may perhaps contain additional testing and controls to evaluate high-quality attributes and process parameters. The extent of structure Place verification depends upon the transform and the extent of possibility affiliated with it.

Making certain regulatory compliance: here Adhering to sector rules is very important, and process validation assists you satisfy these needs persistently. By keeping thorough documentation and demonstrating Management about your processes, you can easily move audits and inspections.

Documentation and compliance: Sustaining extensive documentation is important for demonstrating compliance validation of manufacturing process with market regulations and requirements. This consists of in-depth records of procedures, information, and any variations created over the validation process.

Dilemma-fixing capabilities: Aptitude for diagnosing troubles and implementing helpful alternatives during validation processes.

Guarantee all services and machines are analyzed and confirmed to constantly execute to the required standards, highlighting the requirement of reliable infrastructure in process validation.

Source hubCentral repository for all Lumiform resourcesCustomer storiesReal-earth successes and encounters with Lumiform.

Checks employing generation resources, substitutes or simulated solution. These may be developed with the familiarity with the process and facilities, devices or products.

Retain a safe and conducive setting for manufacturing and storing merchandise with the help of temperature and humidity sensors.

To overcome validation problems, it is important to take a position in instruction and education and learning on regulatory prerequisites.

Through the continued process verification stage, numerous process effectiveness indicators are monitored in order that the process is performing within appropriate restrictions. These indicators may perhaps contain produce, cycle time, process functionality indices, along with other related metrics.

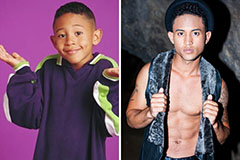

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!